How the modern solder reflow oven works?

To successfully solder surface mount components to a circuit board, the heat should be transferred to the solder alloy paste until its temperature reaches a molten point (217°C for SAC305 lead free solder). The liquid alloy will merge with PCB copper pads and become a eutectic alloy mixture. A solid solder joint will be formed after it cools down below molten point.

There are three ways to transfer heat from heat source to heated objects.

-

Conduction: Thermal conduction directly transmits through a substance when there is a difference of temperature between adjoining regions, without movement of the material. It occurs when two objects at different temperatures are in contact with one another other. Heat flows from the warmer to the cooler object until they are both at the same temperature.

-

Radiation: Heat transfer through radiation takes place in form of electromagnetic waves mainly in the infrared region. Radiation is a method of heat transfer that does not rely upon any contact between the heat source and the heated object. The limitation of radiation is that black body will absorb more heat than white body.

-

Convection: Heat convection is the transfer of heat from one place to another by the movement of fluids such as air or vapour gas. It is also a contactless method to transfer heat as well.

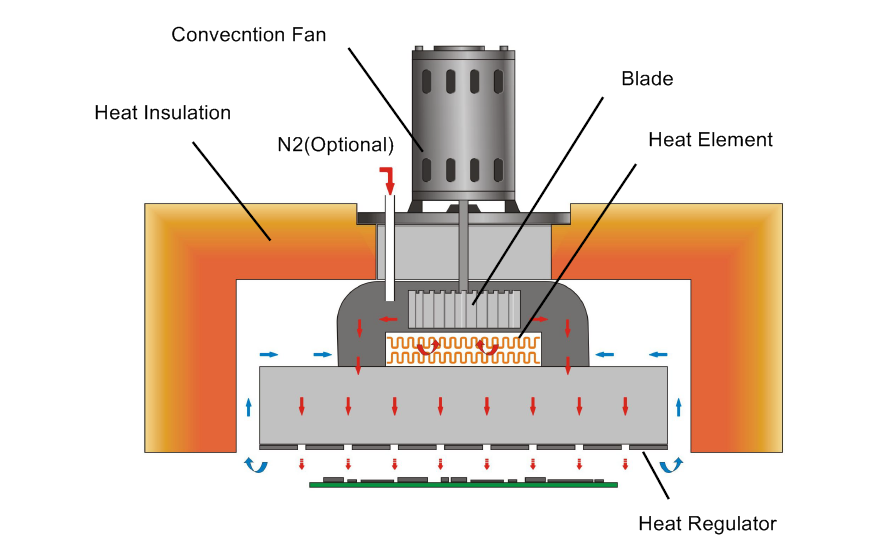

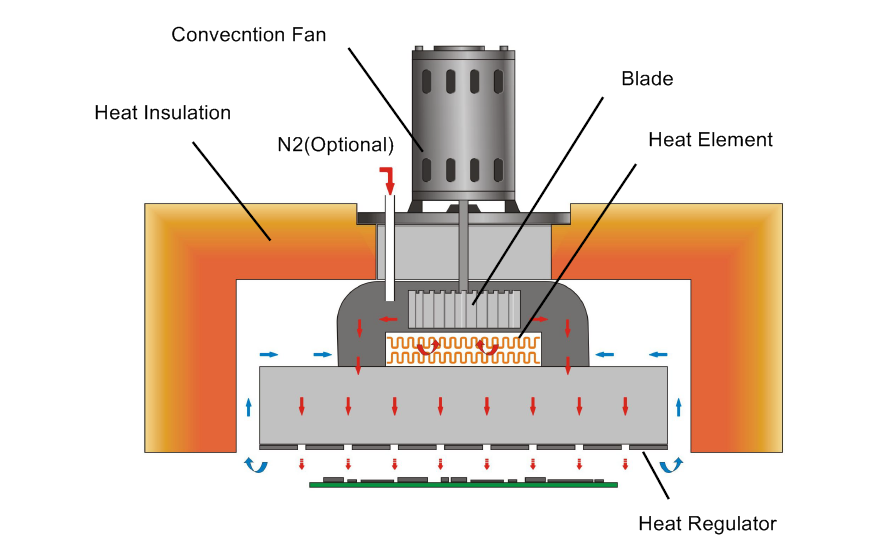

The modern solder reflow oven use the concepts of radiation and convection combined. Hheat is emitted by ceramic heat element with infrared radiation, but it doesn’t deliver it to a PCB directly. The heat will transfer to a heat regulator first to make heat output even. A convection fan will blow the hot air to an inner chamber. The target PCB can will get heat consistency in any spot.

The modern solder reflow oven use the concepts of radiation and convection combined. Hheat is emitted by ceramic heat element with infrared radiation, but it doesn’t deliver it to a PCB directly. The heat will transfer to a heat regulator first to make heat output even. A convection fan will blow the hot air to an inner chamber. The target PCB can will get heat consistency in any spot.

Keywords:

SMT Reflow Oven, Lead free Reflow Oven, Reflow Oven Manufacturer, LED reflow oven, PCB Reflow Oven, Nitrogen Reflow Oven, Dual Rail Reflow Oven, China Reflow Oven, wave soldering machine, Dual Rail Wave Soldering Machine, Nitrogen Wave Soldering Machine, Wave Soldering Machine Manufacturer.

Flason Electronic Co.,ltd provide a full SMT assembly line solutions, including

SMT Reflow Oven,

Wave Soldering Machine,

Pick and Place Machine,

SMT Stencil Printer,

SMT AOI SPI Machine,

SMT Reflow Oven,

SMT Peripheral Equipment,

SMT Assembly line,

SMT Spare Parts

etc any kind SMT machines you may need, please contact us for more information:

wechat whatsapp:+8613691605420, Skype: flasonsmt, Email: sales@flason-smt.com |

|

|

|

FAQ

1) This is the first time I use this kind of machine, is it easy to operate?

There is English manual or guide video that show you how to use machine.

If you still have any question, please contact us by e-mail / skype/ phone /trademanager online service.

2) If machine have any problem after I receive it, how can I do ?

Free parts send to you in machine warranty period.

If the part is less than 0.5KG, we pay the postage.

If it exceeds 0.5KG, you need to pay the postage.

3) MOQ ?

1 set machine, mixed order is also welcomed.

4) How can I buy this machine from you? ( Very easy and flexible !)

A. Consult us about this product on line or by e-mail.

B. Negotiate and confirm the final price , shipping , payment methods and other terms.

C. Send you the proforma invoice and confirm your order.

D. Make the payment according to the method put on proforma invoice.

E. We prepare for your order in terms of the proforma invoice after confirming your full payment.

And 100% quality check before shipping.

F.Send your order by air or by sea.

5)Why choose us ?

A. Gold supplier on Alibaba !

B. Trade assurance to US$54,000 !

C. Best price & Best shipping & Best service ! |

|

The modern solder reflow oven use the concepts of radiation and convection combined. Hheat is emitted by ceramic heat element with infrared radiation, but it doesn’t deliver it to a PCB directly. The heat will transfer to a heat regulator first to make heat output even. A convection fan will blow the hot air to an inner chamber. The target PCB can will get heat consistency in any spot.

The modern solder reflow oven use the concepts of radiation and convection combined. Hheat is emitted by ceramic heat element with infrared radiation, but it doesn’t deliver it to a PCB directly. The heat will transfer to a heat regulator first to make heat output even. A convection fan will blow the hot air to an inner chamber. The target PCB can will get heat consistency in any spot.